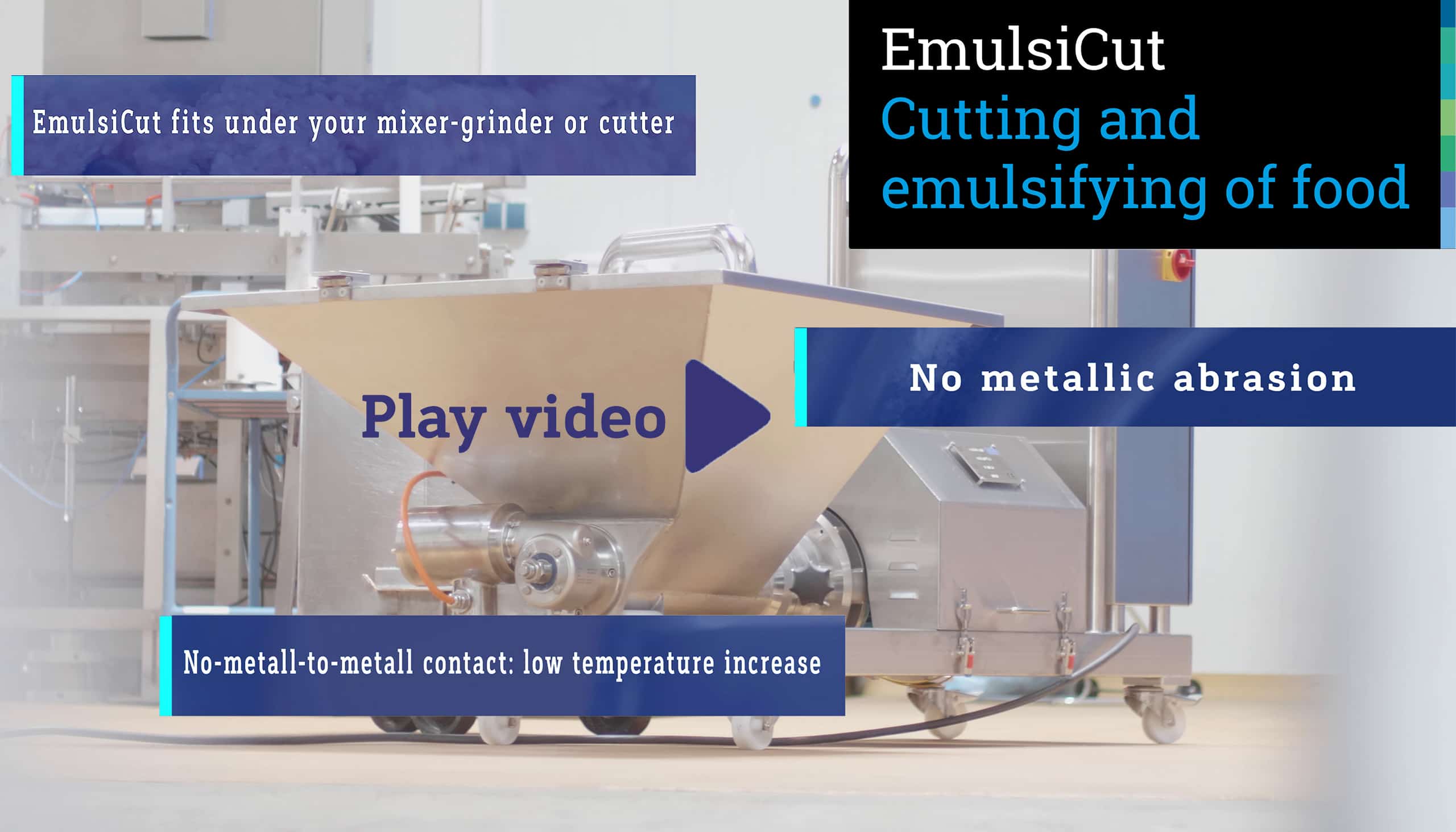

With the EmulsiCut you can cut and emulsify in one step according to the rotor-stator principle.

This means for you:

Contact our experts and benefit from our experience.

At the moment, there is no end in sight to the price increases for gas and electricity. You need machines that offer maximum production output with minimum energy consumption.

No food company can afford a scandal because of poor hygiene. Your machines must guarantee maximum hygiene.

Shortage of skilled workers and pandemic cause production losses due to staff shortages. You can only counteract a production standstill by using machines that are easy to operate and guarantee maximum availability.

Inflation reduces the purchasing power of your customers. You will not be able to fully pass on your increased costs to customers if you want to stay in the market. You need to increase the efficiency of your production in order to be able to offer your customers an affordable product.

High quality is your strongest selling point. Therefore, only rely on machines that guarantee you this quality for a long time.

Economy is in turmoil and not every company will manage to stay in the market. You need to act now and make smart investments to secure your position in the market.

Anton Le Roux

Regional Director

Freddy Hirsch Group (Pty) Ltd.

I would like to compliment you on the LIEDER Emulsifiers that have been delivered to our company in South Africa.

I can confirm that the quality of the workmanship, compared to the previous company we used, is like chalk of cheese from the point of:

We are looking forward to work closely with you in the future, with the LIEDER brand of emulsifiers.

More efficient than a bowl chopper, with low energy consumption and excellent product quality.

The cutting system works according to the rotor-stator principle. The cutting blades are mounted on the cutting ring at a fixed distance between 0.2 and 3 mm from each other. The cutting head is rotating inside of the cutting ring with a motor speed of 3000 rpm. The distance between the cutting head and the blades is approximately 0.1 mm, there is no contact between the cutting ring and the cutting head.

The emulsifier can easily be placed under your mincer or cutter outlet.

125mm

150mm

150mm double

180mm double

7,5 or 11 kW

22 or 30 kW

45 or 55 kW

75 or 90 kW

0.6 – 0.8

1.5 – 2.5

2 – 3.5

3.5 – 5

LIEDER machines have been known for their high quality, reliability and long service life for more than 75 years.

As a medium-sized company that produces exclusively in Germany, we stand for responsible and high-quality mechanical engineering. High quality, both in the selection of components and in the planning and design of our machines, is always our top priority.